Five food packaging machinery dominated the carton molding machine market development

First, it is bag making, filling and sealing packaging machinery. At present, the domestic production of such machinery manufacturers more than 100, with an annual output of 15 million units. Bag making, filling and sealing packaging machinery development trend for the modular structure, multi-column high-speed, high stability, simple transmission machinery, adaptive closed-loop control. Second, metal packaging container processing equipment. National metal packaging container processing machinery production and manufacturing industry has taken shape, the development trend of such products is to improve product performance, improve yield and material utilization.

Second, is to accelerate the technical improvement of products, the development of mercury-free welding and high-performance high-frequency welding power supply.

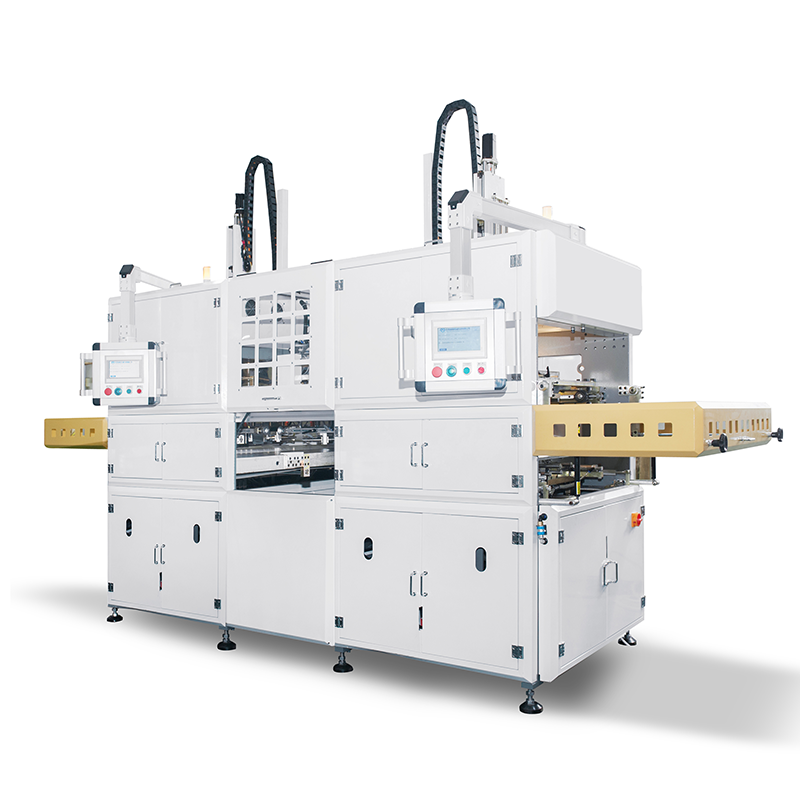

Third, is the corrugated carton (board) production equipment. In the past decade, China's corrugated box molding machine carton machinery industry is developing rapidly, the product range from the corrugated cardboard line to print slotting machine, cardboard gluing machine, cutting machine and other varieties of series, the direction of development in the future is a high-speed complete sets of equipment, and the second is a complete set of medium and lightweight corrugated cardboard box equipment.

Fourth, pulp molding processing equipment. China's paper tableware processing equipment production scale is still relatively small, processing equipment prices are high. In the future, pulp mold tableware processing machinery should be in the molding to reduce the cost of heating molds, improve the heating method, reduce the cost of electricity, improve production and other aspects of increased research.