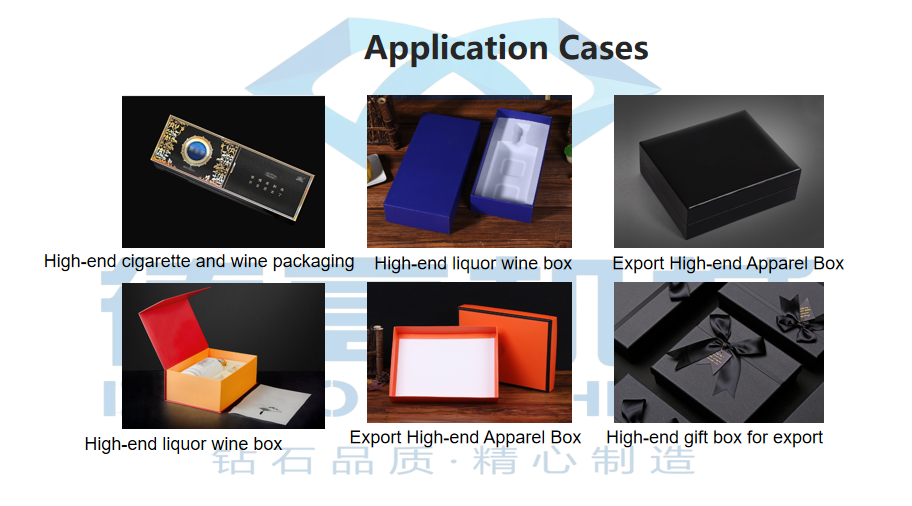

Products

DG-567ED Multifunctional Carton Shell Lining Production Line

Five Advantages Of Products

- Precise alignment, fast transfer speed

- Pressing board presses the box which keeps the box fixed on the case

- Automatic positioning and glue spraying

- Forming modules are customizable and optional

- Fast imaging speed

Product Details

DG-567ED Multifunctional carton shell lining production line

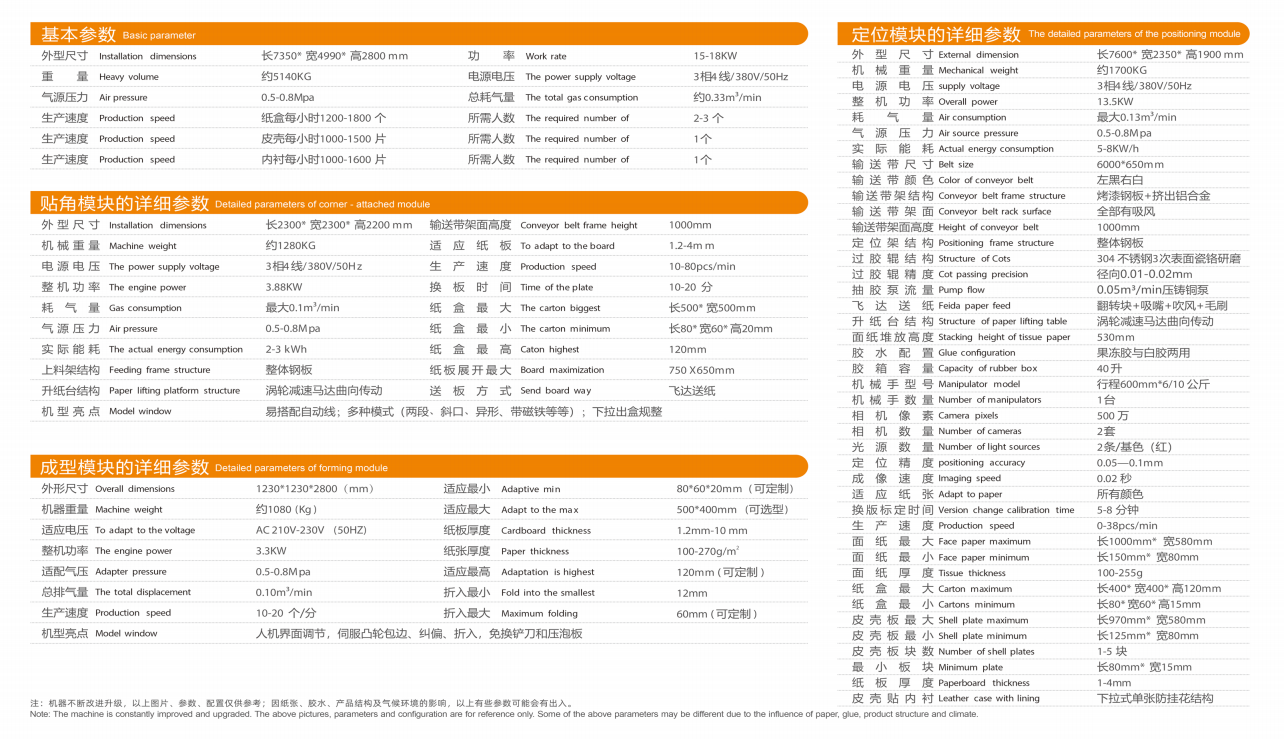

Installation dimensions:7350*4990*2800mm

The required number of:1pcs

Mechanical weight:About 5140KG

Air pressure/Work rate:0.5-0.8Mpa/15-18kw

Carton/Shell/Liningproduction speed:1200-1800pcs/h 1000-1500pcs/h 1000-1600pcs/h

The carton biggest/minimum/highest:500*500mm/80*60*20mm/120mm

Send board way:Fidelity paper feed

Board maximization:750*650mm

Model window of corner-attached module:Easy to match with automatic lines;

multiple patterns (two sections, beveled, shaped, with magnets, etc.); pull-down cassettes are well organized

Model window of forming module:Intelligent adjustment by human-machine

interface, servo cam wrapping, guiding, folding in, no need to change the spatula and pressure foam plate

Features:

The machine is mainly divided into four parts: positioning module, cornering module, molding module and four sides of the shell package, which can realize the production of various types of paper boxes, wooden boxes, plastic boxes, leather shells, liners, such as automatic paper feeding, automatic gluing, automatic cornering, automatic positioning, automatic molding, automatic wrapping and automatic pressure bubble, etc., a series of continuous completion of the technological process. Precise alignment, fast transfer speed, and exquisite box production.

Positioning module of black and white belt, double lens, automatic deviation correction, leather shell board lining positioning, five-piece board positioning. Non-adhesive tape groove and double rising paper table of corner lamination module. The servo cam action of molding module, no-changing spatula and pressure bubble plate are all researched, developed, designed and produced by our company, and have won many national patents.

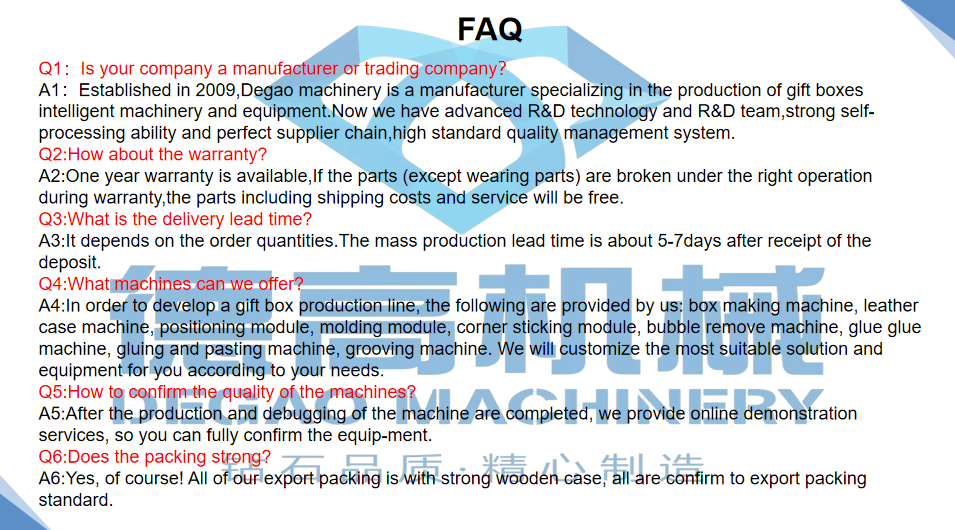

dongguan degao machinery technology co.,ltd

Contact Person: Eva Yin

Department: Sales

Post: Sales Manager

Telephone: +86-189-2827-5267

Landline: +86-135-8077-6960

Company Address: First Floor, Building 4, Baediai Industrial Park, Changping Village, Daojiao Town, Dongguan City, Guangdong Province, China.

Factory Address: Degao Machinery, 1st floor, 4th Building, Baidai Industrial Park, Changping Village, Daojiao Town, Dongguan City, Guangdong Province

Website: www.degaomachinery.com

Previous: DG-567B Multi-Function Automatic ...

-

DG-680 Gift Box Bubble Pressing Machine

-

DG-890 Gift Box Bubble Pressing Machine

-

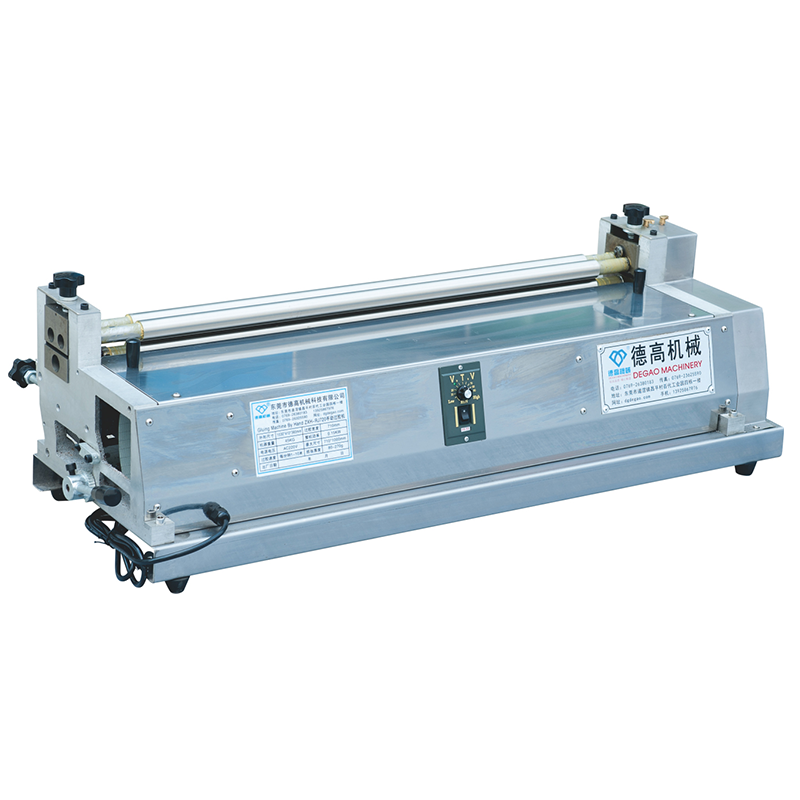

DG-720 Stainless Steel Glue Glue Machine

-

DG-650A/DG-850A Automatic Paper Gluing and Pasting Machine (Feeder)

-

DG-1200A Automatic Feeder Dust-free Grooving Machine

-

DG-567AD Semi-Automatic Box Making Machine

-

DG-567B Multi-Function Automatic Box Making Machine

-

DG-567BC Multifunction Double station Automatic Box Making Machine