Products

DG-500D Servo CAM Automatic Molding Machine

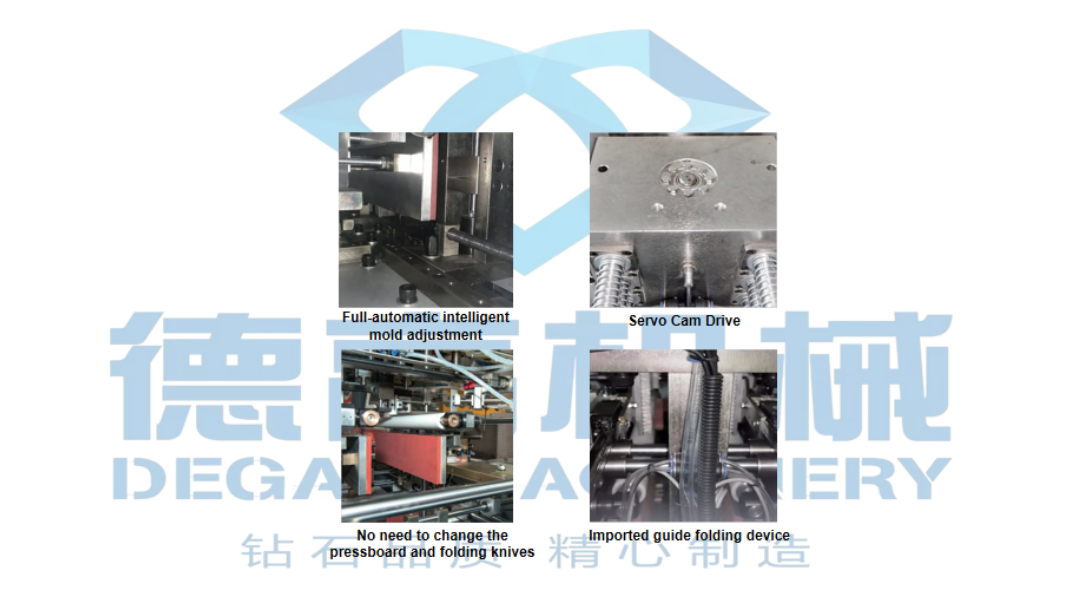

Five Advantages Of Products

- Full-automatic intelligent mold adjustment

- Servo Cam Drive

- No need to change the pressboard and folding knives

- Imported guide folding device

- Customizable and optional

Product Details

DG-500D Servo CAM Automatic Molding Machine

Machine dimension:1100*1000*2800mm

Minimization/Maximum folding:12mm/60mm(customizable)

Mechanical weight:About 1000KG

Production speed:15-25pcs/min

Power supply:3.8kw

Adaptive min/max/highest:80*60*20mm(customizable)/500*400mm(optional)/120mm(customizable)

Glue tank capacity/Adapater Gas Source:AC-220V/0.6-0.8Mpa

Cardboard/Paper thickness:1.2mm-10mm/100-270g/m2

Total dischange:0.1m2/min

This machine integrates wrapping, folding and pressing of carton into one, and uses servo driven helical gear and cam to complete continuous action. It is stable, smooth, precise and durable. It is a relatively reasonable molding machine at present, and also a wise and necessary model for the majority of gift box manufacturers.

Features:

1. The spindle, parting die, brush roller, flanging and bubble pressing are all driven by servo, so the operation is stable and quiet. Smooth and fast.

2. The unique function of twice bubble removing for cam and cylinder can be selected once or twice according to the situation. The air storage adjustable bottom mold lifting design can adjust and control the defoaming force at the bottom of the carton.

3. The helical gear mechanism drives the spindle action, which is stable, accurate, reliable, high output, long service life. The whole machine can realize the slow motion operation of play type, and the cam mechanism can obtain more stable movement. When the speed changes, it can also keep synchronous, and it is easier to observe the production process during debugging.

4. The action of ear folding can be set to 80mm. The guide rail and cylinder have high precision. The stroke can be customized to meet the production needs of different products.

5. The pressure of vacuum suction box can be adjusted, and different pressures can be selected, which is conducive to the smoothness and speed of manual box setting,

6. Quick mold changing and adjusting machine design, program memory function, 15 minutes to complete version transfer.

7. Imported grating protection, fault alarm, fault area display, ensure the safety of operation.

8. Thickened platen, thickened frame and CNC machining center are completed one time to ensure operation stability and assembly standardization.

9. No need to change the folding blade and pressure foam board, which can be used from small to large cartons,

10. The adjustment mode can be manual or upgraded to automatic, and the locking mode can be selected.

dongguan degao machinery technology co.,ltd

Contact Person: Eva Yin

Department: Sales

Post: Sales Manager

Telephone: +86-189-2827-5267

Landline: +86-135-8077-6960

Company Address: First Floor, Building 4, Baediai Industrial Park, Changping Village, Daojiao Town, Dongguan City, Guangdong Province, China.

Factory Address: Degao Machinery, 1st floor, 4th Building, Baidai Industrial Park, Changping Village, Daojiao Town, Dongguan City, Guangdong Province

Website: www.degaomachinery.com

Previous: DG-500B Servo CAM Simplex Box For...

-

DG-680 Gift Box Bubble Pressing Machine

-

DG-890 Gift Box Bubble Pressing Machine

-

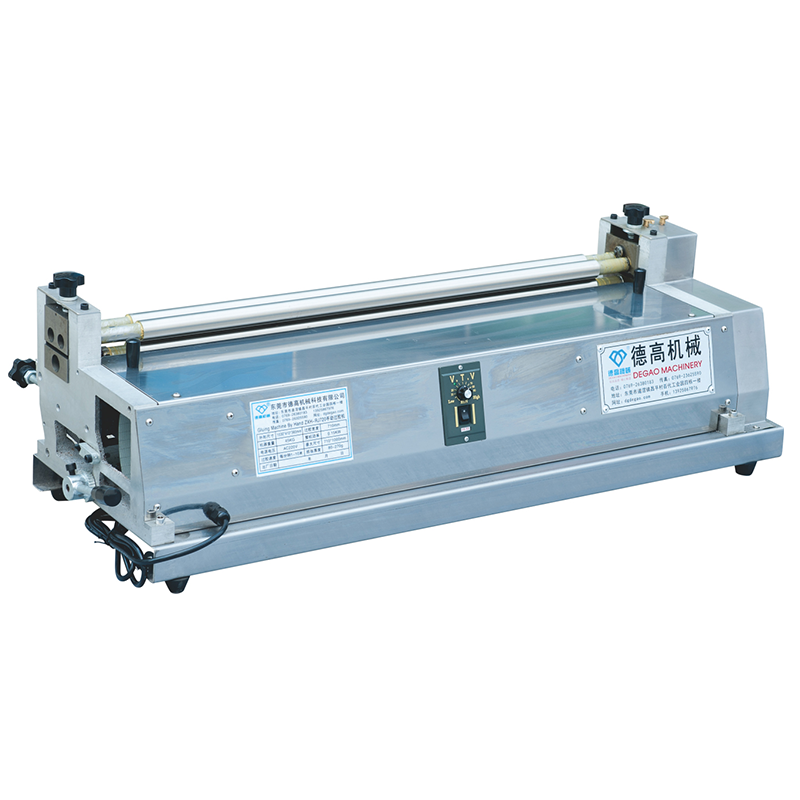

DG-720 Stainless Steel Glue Glue Machine

-

DG-650A/DG-850A Automatic Paper Gluing and Pasting Machine (Feeder)

-

DG-1200A Automatic Feeder Dust-free Grooving Machine

-

DG-567AD Semi-Automatic Box Making Machine

-

DG-567B Multi-Function Automatic Box Making Machine

-

DG-567BC Multifunction Double station Automatic Box Making Machine